WEAR PROTECTION

Tailor-made filler materials

Wear consumables

Wear consumables

High-quality filler materials for perfect welding results

EIPA filler materials are not only used for hardfacing by welding of new components but also for refurbishing of worn components.

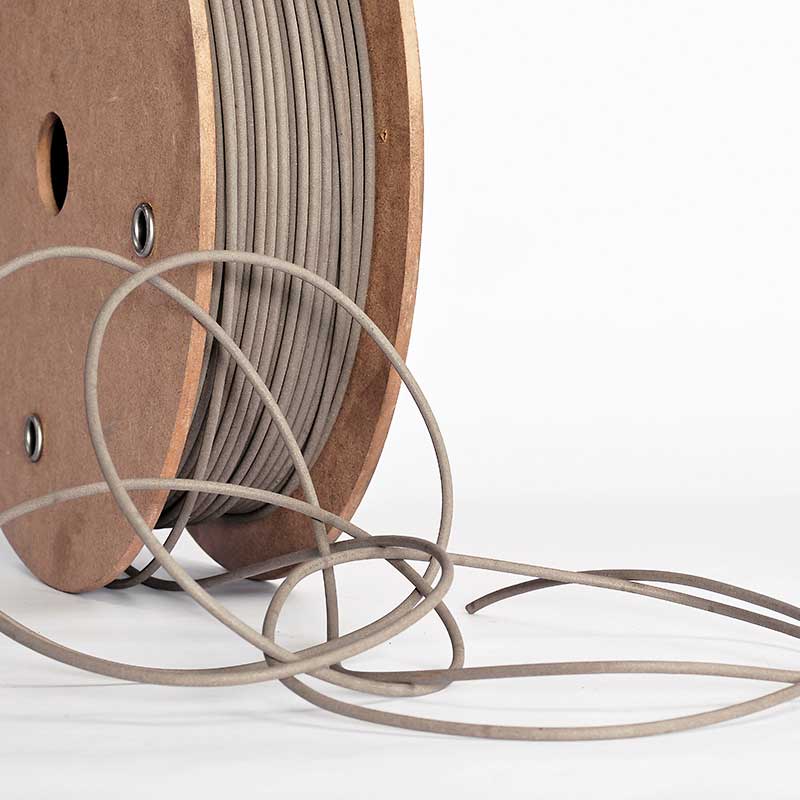

Filler materials for deposition welding, thermal spraying and soldering can be specially developed for your application. For this, several product forms are available:

- Flux-cored wires

- Powders

- Rod electrodes

- Solid wires, solders

- Solid bars

We generally use the following material systems:

- Iron

- Nickel

- Cobalt

- Copper

- WSC, WC

You will receive a customized product, if needed. Either as filler material or as coated component.

Please contact us any time, we will be happy to support you!

Contact:

Mr. Jan Dachtler, M.Eng.

Operations DirectorWurmbenden 10-12, 52070 Aachen

| Telefon: | +49 241 9161744 |

| Fax: | +49 241 9161745 |

| Mobil: | +49 172 320 91 28 |

| E-Mail: | jan.dachtler@eipa.com |

Filler materials / main families

Eipa dur

Weld filler metals for extremely hard-wearing surfacing resistant against abrasion and erosion exposed to moderate impact.

The high hardness and high durability is achieved by the use of various carbide formers and borides. Depending on the alloy, EIPA dur is also suitable for high temperature applications or for corrosive applications.

Mechanical processing is generally only possible by grinding.

Eipa buf

Weld filler metals for buffer layers and build-up layers for various applications as well as for work hardening surfaces. Depending on the load case, EIPA buf can also be used for wet corrosive applications.

EIPA tough

Weld filler metals for applications where high impact loads can be expected. Depending on the alloy, also suitable for applications with additional abrasive load. Generally machinable.

EIPA loy

Nickel-base alloys that are used everywhere, where maximum corrosion resistance and simultaneously high temperature resistance, abrasion resistance and/ or high impact strength are called for. Contains so-called “superalloys”, “self-fluxing alloys” and other standard alloys.

EIPA lit

Cobalt-base alloys, which are generally used for applications where the material is subjected to a load spectrum of temperature, corrosion and abrasion. For extreme load spectra!

EIPA forge

Weld filler metals for coating with materials of the same or different compositions and for repairing hot forging dies. Naturally hardened or precipitation hardened with increased thermal resistance, depending on the requirements.

EIPA cast

Weld filler metals for repairing cast components of different compositions such as grey cast iron for “cold welding” or for coatings with a very low thermal coefficient of expansion.

EIPA tec

Special welding materials, which cannot be the classified according to the existing EIPA material classes due to their special properties.

EIPA roll

Weld filler metals that are particularly well suited for use in cylindrical components for production and transportation of steel such as extrusion cast rolls, guide rollers, forming rolls, roller conveyor rollers, etc. Depending on the alloy, increased resistance to metal-on-metal friction and thermal shock resistance with increased corrosion resistance.

Depending on the alloy, can also be used for applications subject to cavitation.

EIPA tung

Weld filler metals with various tungsten carbidesand hard metals for maximum wear resistance. The special feature of these additives lies in the properties of the weld metal deposit, which is a composite material.

Depending on the application, you can choose between different types of tungsten carbide, grain size and grain shape, and welding materials with hard phases in hybrid forms such as spherical FTC + broken FTC are possible.

EIPA spray

These are filler materials which were exclusively developed for thermal spraying with different spraying processes. These are available in different trading forms and packaging.

Please contact us anytime!